JIT: What is Just-in-Time Logistics?

In a time when accuracy, speed, and efficiency are critical, knowing the subtleties of Just-In-Time (JIT) logistics can revolutionize your company.

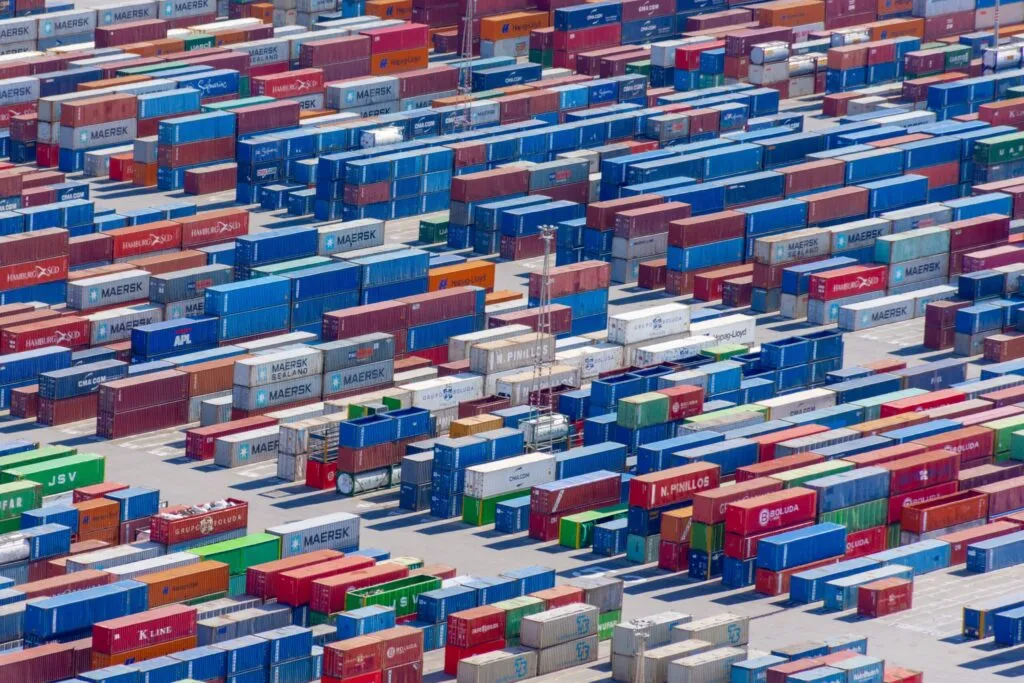

Imagine a flawless symphony of manufacturing, transportation, and inventory management, all expertly orchestrated to guarantee that supplies and materials arrive at the exact moment needed, no sooner, no later. The goal of JIT logistics is to create this harmonies symphony.

We will go further into the history, tenets, and practical uses of just-in-time (JIT) logistics as we explore its layers in this blog series. This blog is for everyone interested in learning more about the complex network that supports modern business, regardless of experience level in logistics.

How JIT Works

Just-in-time logistics is a well-planned strategy that guarantees goods and services are delivered precisely when needed. It functions with lean manufacturing techniques, small batch production methods, and precise demand forecasts. Tight production schedules and effective supply chain management are essential, and the Kanban system indicates when materials need to be restocked. While efforts are being made to optimize processes continuously, Total Quality Management techniques ensure that standards are of the highest caliber.

JIT is a potent tactic for companies looking to maximize operations and maintain competitiveness because of its advantages, which include lower inventory costs, shorter lead times, more efficiency, better quality, and increased flexibility.

Where Did It Come From?

Just-in-time was developed in Japan and made popular by Toyota, a well-known Japanese automaker. The idea first surfaced in Japan in the 1950s and 1960s in reaction to the country’s post-World War II economic difficulties. Toyota’s production system creatively concentrated on decreasing waste, lowering inventory, and improving efficiency to make the most of limited resources and money. The leading developer of JIT’s ideas is recognized as Toyota engineer Taiichi Ohno. He was influenced by several things, such as W. Edwards Deming’s efficiency theories, American supermarkets’ inventory control practices, and Henry Ford’s assembly line tactics.

Toyota’s successful introduction of Just-In-Time (JIT) production and supply chain strategies changed the world, inspiring broad industry adoption and making it a pillar of contemporary lean management approaches.

Benefits of Just-in-Time Logistics

Just-in-time logistics is a shining example of operational excellence, providing many enticing advantages that have the potential to change companies completely. Toyota led the way in this strategic strategy, which has been adopted by many other industries and creates an elegant balance between responsiveness, accuracy, and efficiency. Here’s a closer look at the main benefits that JIT logistics offers.

Reduced Inventory

By providing goods and supplies precisely when needed, just-in-time (JIT) logistics optimize inventory management by removing the need for unnecessary hoarding. This decrease in inventory levels frees up important warehouse space, lowers storage costs, and keeps money out of unsold goods. Organizations function with less, more economical stock, guaranteeing that monetary assets are employed effectively.

Lower Operational Costs

JIT logistics reduces waste, idle time, and excessive expenses by optimizing manufacturing processes. Businesses can save much money by lowering holding and handling expenses when their inventories are smaller. Reduced labor hours, efficient production cycles, and lower overhead expenses all contribute to lower operational costs, which improve the organization’s overall financial standing.

Faster Deliveries

JIT logistics is all about timing and accuracy; it makes sure that supplies arrive precisely when they’re needed for manufacturing. This same punctuality also applies to product deliveries, allowing companies to precisely and quickly complete consumer orders. Businesses can exceed consumer expectations and meet market demands with agility thanks to optimized supply chain operations that improve delivery speed.

Better Responsiveness

Utilizing JIT logistics improves a business’s ability to adapt to changing consumer demands and market conditions. Businesses may capitalize on new trends, release new goods more quickly, and swiftly adjust to changing demands when lead times are shortened and manufacturing schedules are adjusted. This flexibility helps the business become more responsive to changing client needs in real-time, which in turn builds customer connections and establishes it as a leader in the industry.

JIT Challenges

Adopting Just-in-Time (JIT) logistics is a strategic initiative with many advantages, but it’s not without challenges. Businesses navigating the complexity of modern supply chain management need to take a nuanced approach to maintain the delicate balance between efficiency and agility. Here, we examine a few particular difficulties related to just-in-time logistics and provide insights into potential solutions.

Difficulty of Accurate Demand Forecasting

The foundation of just-in-time logistics is accurate demand forecasting, which is still one of the biggest obstacles. Accurately projecting future needs is difficult due to shifting customer behavior, seasonal fluctuations, and shifting market demands. The precisely calibrated JIT process can be upset by inaccurate projections, which can result in overproduction or stockouts. Demand forecasting accuracy can be improved by using sophisticated analytics, utilizing historical data, and encouraging supplier and customer communication. This will help businesses better coordinate their production and inventory levels.

Possibly Severe Impact of Minor Disruptions

JIT logistics relies on flawless coordination and accurate scheduling to operate on extremely narrow margins. Even minor disruptions, such as unplanned equipment malfunctions, supplier problems, or delays in transit, can have serious consequences. These issues may result in higher lead times, postponed delivery, and manufacturing bottlenecks, jeopardizing client satisfaction and straining ties with suppliers. Businesses must invest in backup plans, diversify their supplier base, keep buffer stockpiles of essential components, and foster effective communication channels throughout the supply chain to reduce these risks. The integrity of the JIT system can be maintained, and the effects of disruptions can be reduced by being ready for unanticipated events.

Hidden Costs

Although just-in-time logistics is praised for its effectiveness, it occasionally hides unintended expenses. Businesses may neglect other expenses in an effort to cut obvious costs, including inventory holding costs. The expenses incurred by expediting shipments, making emergency modifications, or upholding strict quality control protocols can accumulate. Furthermore, companies may place smaller, more frequent orders due to the pressure to maintain low inventory levels, resulting in greater transaction and transportation expenses. To ensure that the benefits of JIT outweigh its overall costs, companies must do a thorough cost analysis that accounts for both visible and hidden charges.

Implementing JIT Logistics

JIT logistics implementation calls for a systematic strategy that combines accuracy, adaptability, and foresight. To overcome potential obstacles, this strategic methodology, which is praised for its effectiveness and affordability, requires a full awareness of the supply chain ecosystem and a proactive mindset. Here, we examine crucial tactics for executing JIT logistics efficiently, concentrating on particular areas that require consideration and insight.

Identify Bottlenecks and Inefficiencies

A critical first step in JIT implementation is identifying bottlenecks and inefficiencies within the existing supply chain processes. Finding the places where delays and waste arise in production workflows, inventory management systems, and transportation networks is made more accessible by thoroughly examining them. Once located, these bottlenecks can be removed by integrating technology, streamlining processes, and providing personnel training. Businesses facilitate a more seamless JIT deployment by optimizing procedures and getting rid of inefficiencies.

Become Data Savvy

For just-in-time logistics, data is essential. To make wise decisions, businesses must leverage the power of advanced analytics and data-driven insights. Businesses may improve the accuracy of their demand forecasting, optimize inventory levels, and streamline production schedules by reviewing historical sales data, market trends, and supplier performance measures. By putting in place robust data management systems and utilizing cutting-edge technologies, like machine learning and artificial intelligence, organizations can anticipate changes in demand and make proactive adjustments to their JIT plans.

Design the Process in Detail

Process design and careful planning are essential for JIT logistics. Every stage of the supply chain needs to be meticulously planned, from procurement to manufacture and delivery. Work closely with suppliers to coordinate delivery dates and create dependable communication routes. Create manufacturing procedures that optimize batch sizes, cut down on setup times, and simplify changeovers. Establish a strong quality control system to find errors early on and stop problems from happening later. Paying close attention to these particulars guarantees that the JIT implementation will smoothly fit in with the overall goals of the business.

Manage the Risk of Disruptions

In just-in-time logistics, it is critical to identify and reduce the risk of disruptions. Building solid connections with several trustworthy sources minimizes the effect of possible interruptions from a single source. Create backup plans and alternate transportation routes if the supply chain experiences unforeseen delays or disruptions. Keep safety stock of essential parts on hand to reduce the possibility of stockouts in the event of unexpected supply disruptions or demand spikes. Businesses can maintain the integrity of their JIT system and guarantee a steady flow of resources and products by proactively addressing these risks.

Is JIT Worth It?

The value of Just-in-Time (JIT) logistics implementation for a company depends on a number of important aspects. Businesses with complicated or highly customized production processes may find adapting difficult, whereas industries with consistent demand patterns and dependable suppliers may find it most beneficial. Evaluation of financial resources, including hidden costs, is crucial, and a sustained commitment to JIT as a component of the business’s strategic strategy is essential. JIT’s effectiveness also greatly depends on the company culture, employee engagement, and openness to change.

If you find JIT to be a strategic fit for your operations, navigating the complexities of implementation is crucial. For businesses looking to optimize their supply chain strategies and explore the potential benefits of JIT logistics, seeking expert guidance is invaluable. At Carolina Logistics Inc., we specialize in tailoring logistics solutions to meet your unique requirements. Our team of professionals is dedicated to providing top-notch services, ensuring seamless implementation, and maximizing the advantages of JIT logistics. Let us be your trusted partner on this transformative journey, guiding your business toward enhanced efficiency, reduced costs, and improved customer satisfaction. Contact us today and discover how Carolina Logistics Inc. can empower your supply chain success.